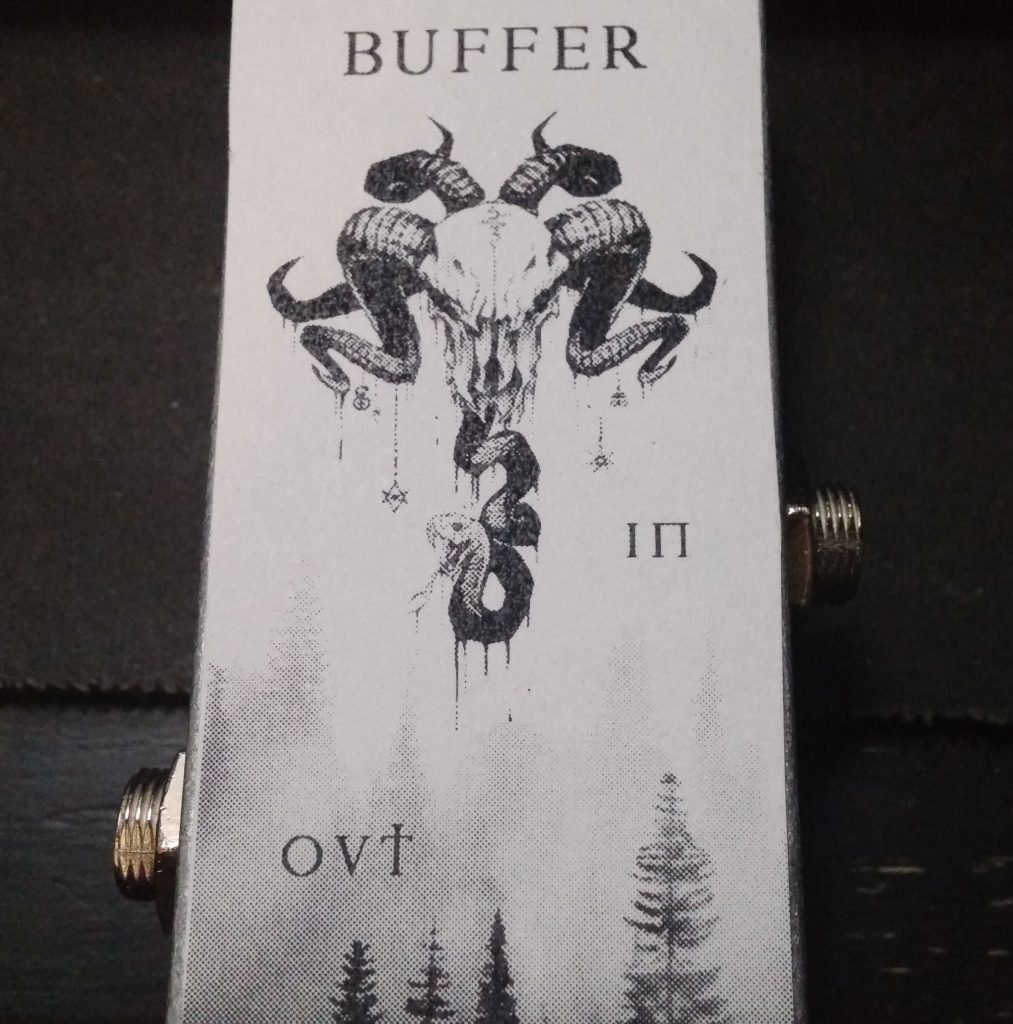

Diy panels using toner transfer method for eurorack modular synths

So first of all thanks to Stereoping for this tutorial i found on their site. I just wanted to add some of the challenges i went through, adjustments, etc…

I started using sticker adhesive paper, super nice results but it’s paper…

This method for toner transfer is easy but you have to do it right.

First heat up your iron. Mine is old and weak apparently so i had to use a thinner cloth.

Prepare the design on your favorite software, i use illustrator.

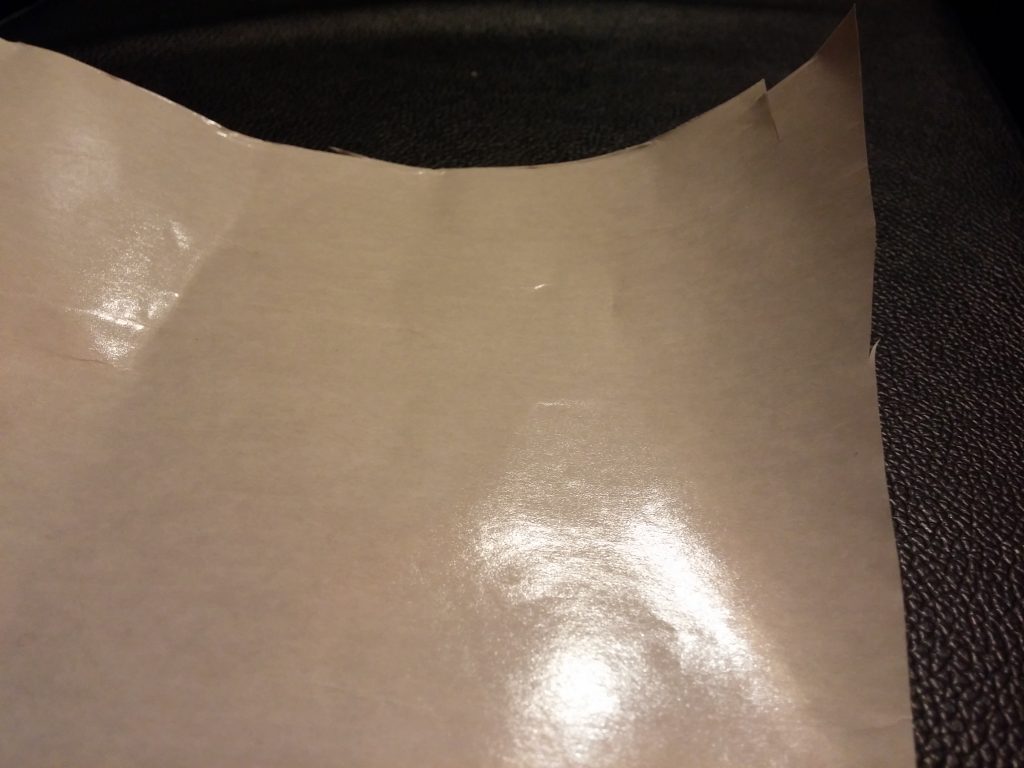

Then flip everything mirror effect and print on glossy paper, i use sticker under paper but you can use anything that’s glossy even magazine papers. I usualy stick them to a regular sheet at the center and put it in the printer. This works using laser printer only, don’t waste time using inkjet and dont put paper with a coat or glue on them in the printer it will ruin your printer.

Then you just put the design at the right place on your panel/enclosure and place the iron on it with a light cloth to make the heat even out better and not burn the paper too quick.

I usualy let the iron on it for about 5 minutes, after 1-2 minute it starts to stick to the aluminum and then you can move around a bit with the iron to be sure you cover all the spots with heat, move slowly, not too much pression it could move the design.

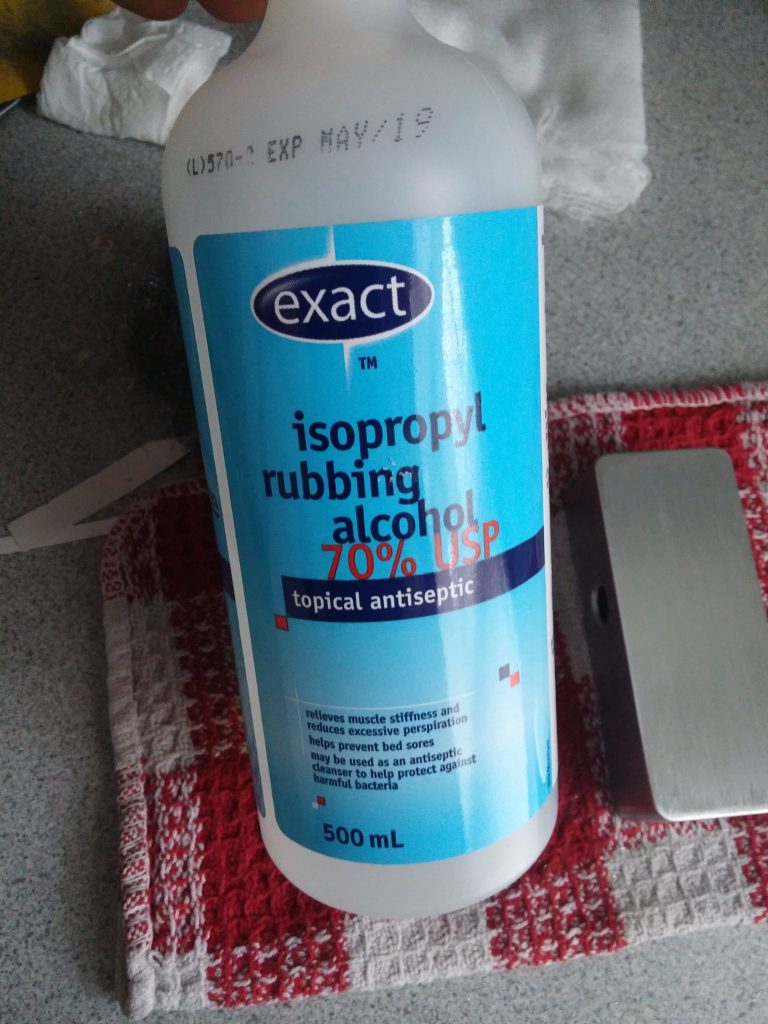

The key is to clean the surface with steel wool and then alcohol for removing dust.

Even if you think it’s not dirty, trust me it is, and it helps a lot for the toner to transfer properly.

I use this cheap one, it works fine…

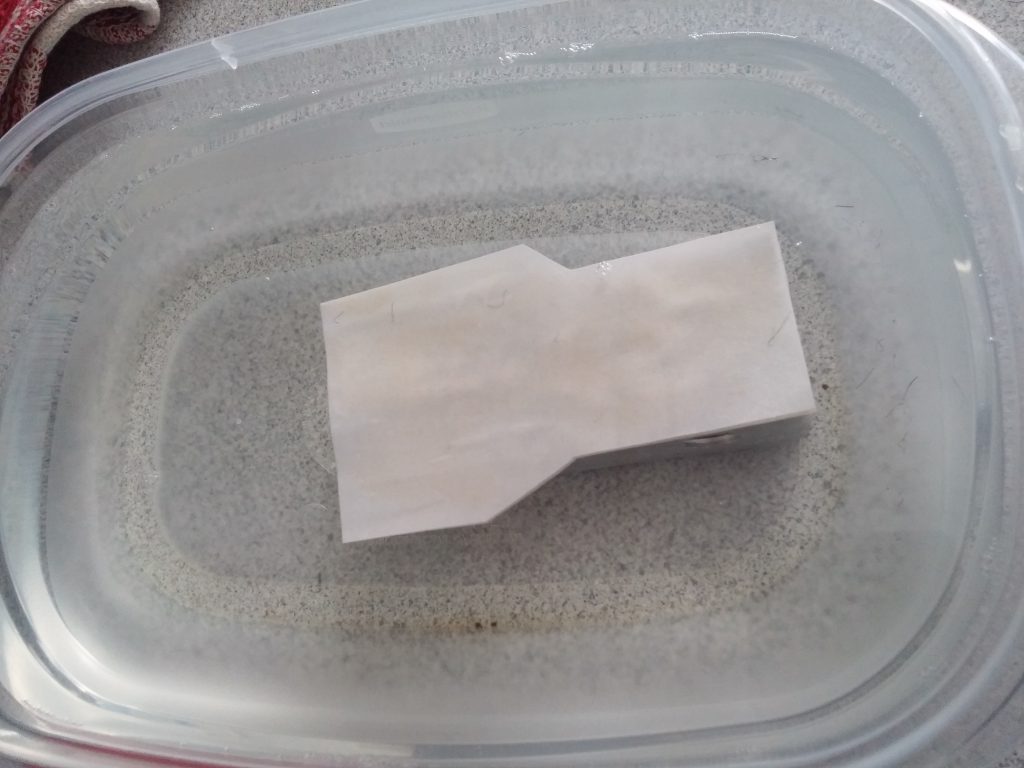

Then you put it in a bowl with water, not cold, not hot, just warm and a little dishwasher detergent. I wait for 10 minutes, maybe a bit more is better i didnt tried.

Here is the final result. I tried many times before getting decent results because my iron isnt that hot. You have to find the sweet spot for time and heat also the thickness of the cloth between. You can see too much brushed on my enclosure, i’ll post better results soon as i make more of them.

Another test before making some real ones…

And i just finished assembled the drill press, that makes the holes a lot to center them.

Step bits are really useful! Check them on ebay, aliexpress, amazon etc.

Using raw aluminum panels.

I’ll add more later but for now i’d just say, use a nail to punch where the holes need to go then use a small bit, then use the stepped bit, this way you can have precise and aligned holes.

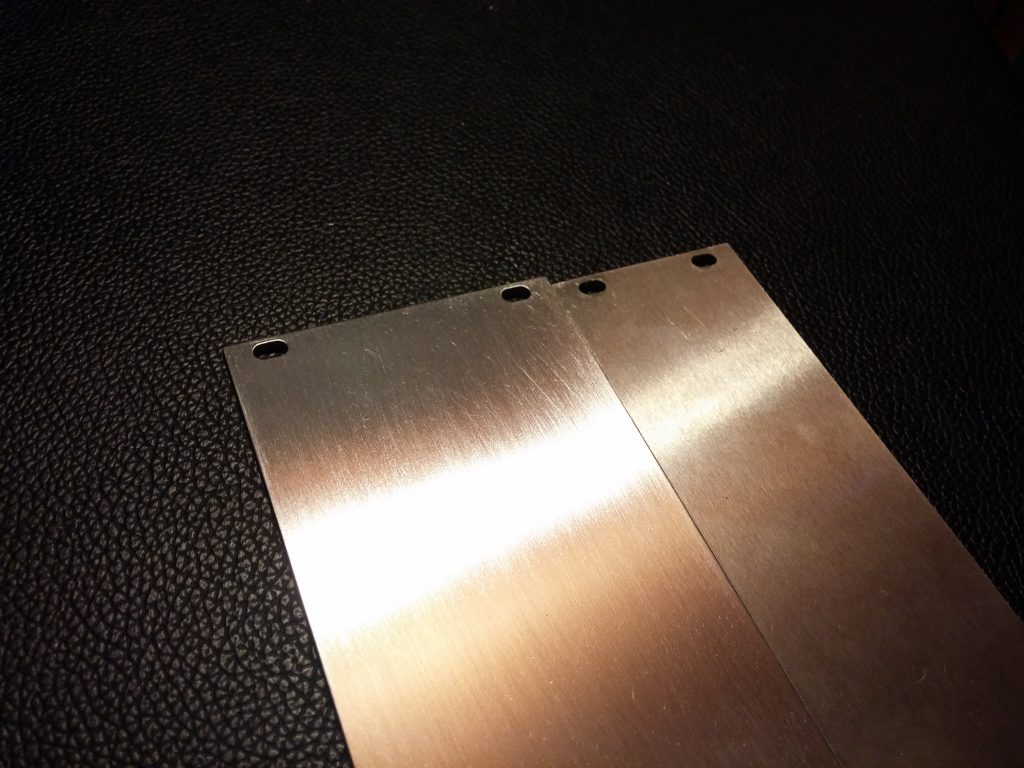

With some steel wool brushing, looks super nice after.

Left one is brushed, right is not.

Still work in progress. I will try to update this page as i make more and better.